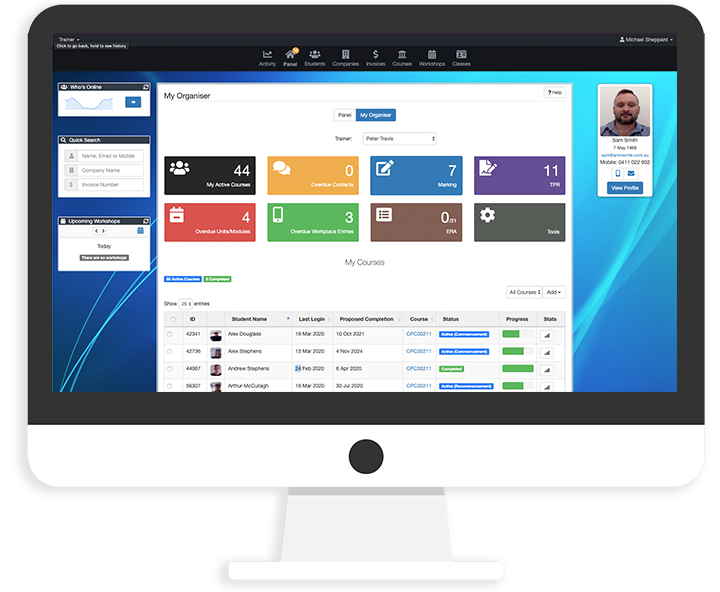

Learning Management System

The Australian cloud-based LMS.

All of your training needs in one package.

Why Choose Us

Ammonite is founded on decades of leadership in education and innovative learning design, mixed with the latest in technology. Our value proposition to our clients is delivering quality training with a focus on compliance, automation of administrative processes and workflows, and embracing state of the art technology for our learners and educators. In addition, many our customers have contributed exciting features that has made Ammonite more powerful than we could have imagined.

About Ammonite

Authenticity

How do online training systems make sure it is the learner who is accessing the material? Ammonite provides our VAT technology which uses webcam or smart phones to capture photos of the learner.

Learn moreCompatibility

Learners and educators can access Ammonite using any device at any time. Are you out and about on a mobile phone and need to do something urgently? Not a problem as you have uninterrupted access from anywhere.

Valid Assessments

It is common to see 'diplomas of clicking', where learners can just click their way through quizzes. Ammonite has developed our Validity and Authenticity Technology which requires learners to know the topic to advance through the quiz.

Learn MoreOnline Classroom

Live video and audio feeds of learners can be sent into an online classroom for monitoring by an educator. This works natively inside the web browser using WebRTC which is available on practically all devices/browsers.

Learn moreMapping

Ammonite includes a mapping tool that allow assessments, resources and workplace activities to be mapped to a compliance element such as the Unit of Competency or the Australian Core Skills Framework.

Learn moreLLN

Ammonite supports an LLN quiz that the learners can undertake to give an indication of the learners ability in the 5 key areas: Learning, Reading, Writing, Oral Communication and Numeracy.

Learn more